I was contemplating pulling out the shelf in the bilge area but after quite a bit of looking I found one of these pumps from Whale.

http://www.whalepumps.com/marine/product_list/8/55/

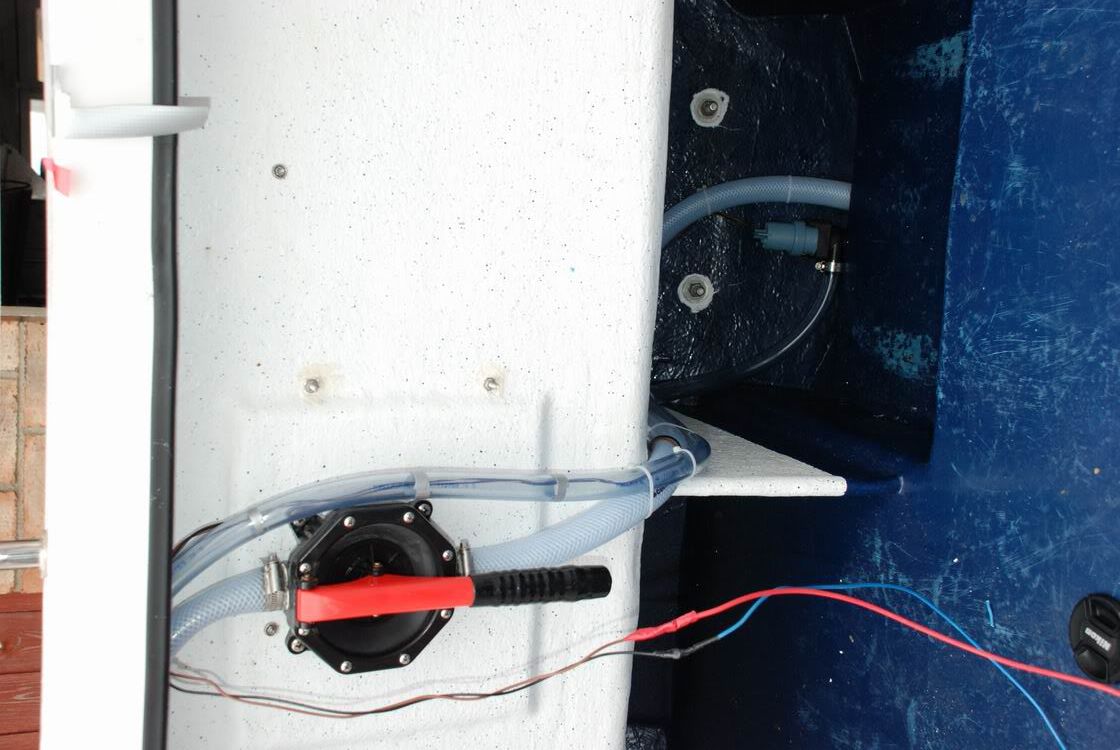

They are a perfect fit in behind the shelf in the bilge area. I managed to mount this one beside the existing manual pump hose pipe.

Here is the housing beside the manual pump hose

You can see how thigh you are for space here

Here is the pump installed.

The next decision was how to plumb it up. I really didn't want to have a second through hull connection, so I bought a y splitter.... They when thinking about the plumbing I realised that I needed a valve with a selector switch to maintain backpressure.....doh. If I installed the y splitter I simply would have pumped the water back into the bilge area.

Back to the chanderly store to pick up a y valve with selector... The bits and pieces were now starting to cost way more that the bilge pump....

Back into the boat to have a look. No matter how I tried I couldn't get the y valve to fit nicely, as it had to be fitted near the top of the transom and it is a bulky piece of plastic...... sh!t...

I then decided to bite the bullet and just fit a second through hull outlet. Back to the chanderly store to pick up some more water pipe and a through hull connection. The Good thing was I has so many other bits to give back I was able to buy a nice outboard lock with the left over cash....

After a few nervous phone calls to Jim I was back in the boat and ready to cut a hole in my boat.

Two outlets

Inside view

After this it was just a simple matter of running in the water hose. I followed the route for the manual pump hose and just tie wrapped the two pipes together.

This turned out to be very neat.

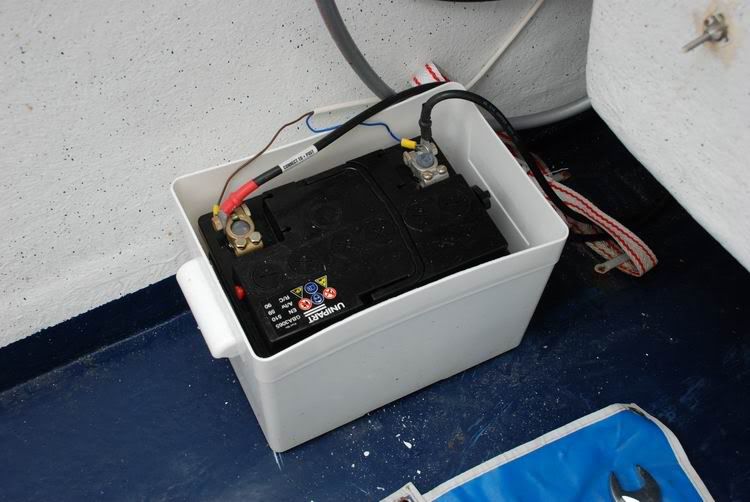

Next was the wiring. I was not happy with the thickness of the existing wiring provided with the boat. It was basically just some thin household electrical cable. I'd say it is about 3mm sq. I was worried the heavier draw from the bilge pump. As I was extending the bilge cable to the switch panel, I decided what the hell, let's kill the two birds with the one stone. I had a rummage around work and managed to fins some 7mm and 8mm blue and red cable. Blue was to be my negitive. I put some black electrical tape at each termination point just to "keep it to code" as our US friends might say.

Here is the thin cable

Here is the new cable attached to the battery.

I am really happy with the result.... I still think cutting a hole in a perfectly good boat is a daunting task, but if you measure twice (or 4 times) and cut once, you'll be fine.

Thinking back, I should have went the with the second fitting from the start and saved myself a lot of messing around, but I got there in the end.

Oh yeah,,,

Here is a pic of the outboard lock I picked up

Kev