Adding PTT

Mon Aug 09, 2010 1:43 pm

Hello All

Just thought I would put this up in case anyone is interested.

In August last year I bought a 12 foot sea nymph Aluminium with a nice 2007 10 hp merc. I like to bring the family out in in for a run and getting the Strikeliner out everytime for this was becoming a bit of a pain (as its housed indoors).

Brought her out a few times on the Shannon and Ree but it became fairly obvious that she was gonna be out gunned in any rough weather and even for very inshore sea work....so away she went. Heres the nymph before I sold her:

After selling the nymph I recently bought a 14 foot Dory for messing about in and for inshore and lake fishing.

The Dory has a 1996 Sukuzi 65hp 2 stroke auto injection and was nicely set up with four individual seats, all engine sensors working, auto bilge pump, decent trailer with new shocks and new winch. Got her for 300 more then I sold the nymph for so i was happy with that.

I added rod rests, leather seats in front, sounder, GPS and a few other bits. Changed the impellor and cleaned out the oil tank etc. Engine was very clean all in all with only freshwater use from what I can see (bought it from a guy on the Shannon ). But what bothered me was that the engine didn`t have PTT which was a real pain. The previous owner had fitted a stop gap solution of a winch added to the transom with the strap running up through the top of the ski pole supported by an A frame. It worked to get the engine up but was hardly ideal.

Here is a picture of the dory with the winch in place at the back.

I wasn’t happy with the lack of PTT so began looking into alternatives. A new PTT for a Suzuki DT65 $1700 from the US for the motor only .. no chance.

A universal one from CMC was working out €1200 Euro from the states with most likely customs to be added or around €1250 from Europe all in all.

Looked on EBAY but the new ones were in parts only almost as expensive and I couldn’t find a complete second hand unit. I didn’t want to fork out half what I paid for the boat so these options were out.

At the start of July I found a guy over in mayo selling a damaged Suzuki DT75. He reversed onto a rock and smashed the prop and shredded the gearbox but he said everything else was working including the ptt. So one Saturday we drove over to take a look. Found the engine to be in Ok condition and even better the PTT looked good and seemed to be working. There was no obvious leakage and the motor sounded good.

Got it for €280. Took it home and stripped off the PTT and mounting and also scavenged it for any spare parts that might be compatible with my 65. Took off the starter, oil level sensor and float, oil pump, clips, tubing and so on and then sold on the rest to a guy who needed the carbs for 100 euro. So it cost us 180 for what we needed.

Here is that engine just after we took off the PTT:

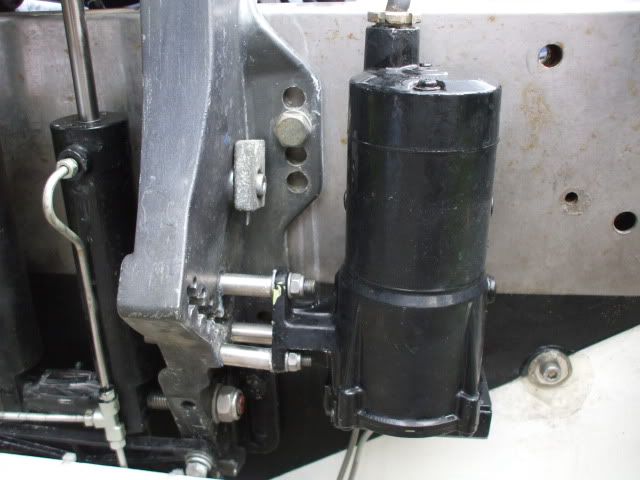

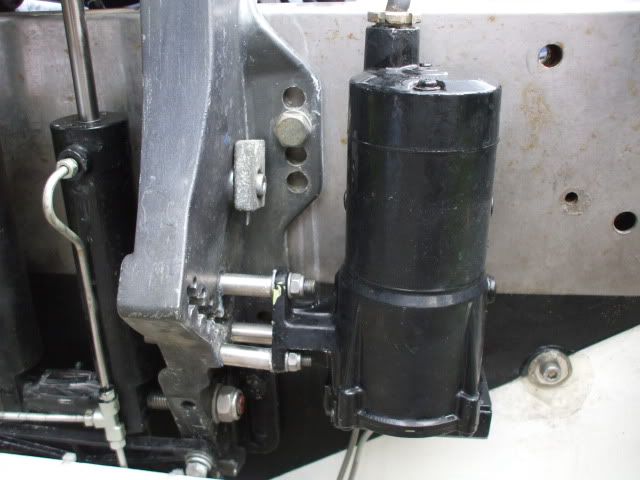

Now it was obvious that the full PTT with mount and brackets would not fit the 65 so some modification was needed. The first thing to do was to free the motor, pipes and cylinders from the mount. So we cut the mount off with an angle grinder which left the two cylinders with pistons just connected to the motor via the hydraulic pipes. At this point checks suggested the pressure was good and that the PTT would have no problem lifting the 65.

So to mount it to the 65 we firstly needed to take out the trim bar and remove the tabs and springs that lock onto the trim bar from the inside of the engine mount. That was all removed easily enough. It all looked like it was going to fit ok.

Nest the top of the pistons were hung into the PTT holes in the engine , which luckily where still there for a non-PTT engine. We used a high quality stainless 12 mm bolt for this.

Then the position was marked and the bottom of the cylinders lined up with a hole the engine mount (on the transom). There was already a hole there but we opened in out to 14mm from 12. We mounted the bottom of the cylinders with stainless 14 mm bar through these holes. Everything lined up nicely. We left the original spacer in there between the two cylinders as it has a grease nipple. We put the bottom plate back in place to support the cylinders.

Next we just needed to mount the motor on the side of the transom and there were already holes there to line it up, we just needed to add spacers.

Next the wiring and we wired direct from the high amp cables from the motor to a rocker switch mounted just behind the throttle control.

Checked it out and bingo.happy days. Seems to be working well.

Click below for a vid

Total project cost €205

Just thought I would put this up in case anyone is interested.

In August last year I bought a 12 foot sea nymph Aluminium with a nice 2007 10 hp merc. I like to bring the family out in in for a run and getting the Strikeliner out everytime for this was becoming a bit of a pain (as its housed indoors).

Brought her out a few times on the Shannon and Ree but it became fairly obvious that she was gonna be out gunned in any rough weather and even for very inshore sea work....so away she went. Heres the nymph before I sold her:

After selling the nymph I recently bought a 14 foot Dory for messing about in and for inshore and lake fishing.

The Dory has a 1996 Sukuzi 65hp 2 stroke auto injection and was nicely set up with four individual seats, all engine sensors working, auto bilge pump, decent trailer with new shocks and new winch. Got her for 300 more then I sold the nymph for so i was happy with that.

I added rod rests, leather seats in front, sounder, GPS and a few other bits. Changed the impellor and cleaned out the oil tank etc. Engine was very clean all in all with only freshwater use from what I can see (bought it from a guy on the Shannon ). But what bothered me was that the engine didn`t have PTT which was a real pain. The previous owner had fitted a stop gap solution of a winch added to the transom with the strap running up through the top of the ski pole supported by an A frame. It worked to get the engine up but was hardly ideal.

Here is a picture of the dory with the winch in place at the back.

I wasn’t happy with the lack of PTT so began looking into alternatives. A new PTT for a Suzuki DT65 $1700 from the US for the motor only .. no chance.

A universal one from CMC was working out €1200 Euro from the states with most likely customs to be added or around €1250 from Europe all in all.

Looked on EBAY but the new ones were in parts only almost as expensive and I couldn’t find a complete second hand unit. I didn’t want to fork out half what I paid for the boat so these options were out.

At the start of July I found a guy over in mayo selling a damaged Suzuki DT75. He reversed onto a rock and smashed the prop and shredded the gearbox but he said everything else was working including the ptt. So one Saturday we drove over to take a look. Found the engine to be in Ok condition and even better the PTT looked good and seemed to be working. There was no obvious leakage and the motor sounded good.

Got it for €280. Took it home and stripped off the PTT and mounting and also scavenged it for any spare parts that might be compatible with my 65. Took off the starter, oil level sensor and float, oil pump, clips, tubing and so on and then sold on the rest to a guy who needed the carbs for 100 euro. So it cost us 180 for what we needed.

Here is that engine just after we took off the PTT:

Now it was obvious that the full PTT with mount and brackets would not fit the 65 so some modification was needed. The first thing to do was to free the motor, pipes and cylinders from the mount. So we cut the mount off with an angle grinder which left the two cylinders with pistons just connected to the motor via the hydraulic pipes. At this point checks suggested the pressure was good and that the PTT would have no problem lifting the 65.

So to mount it to the 65 we firstly needed to take out the trim bar and remove the tabs and springs that lock onto the trim bar from the inside of the engine mount. That was all removed easily enough. It all looked like it was going to fit ok.

Nest the top of the pistons were hung into the PTT holes in the engine , which luckily where still there for a non-PTT engine. We used a high quality stainless 12 mm bolt for this.

Then the position was marked and the bottom of the cylinders lined up with a hole the engine mount (on the transom). There was already a hole there but we opened in out to 14mm from 12. We mounted the bottom of the cylinders with stainless 14 mm bar through these holes. Everything lined up nicely. We left the original spacer in there between the two cylinders as it has a grease nipple. We put the bottom plate back in place to support the cylinders.

Next we just needed to mount the motor on the side of the transom and there were already holes there to line it up, we just needed to add spacers.

Next the wiring and we wired direct from the high amp cables from the motor to a rocker switch mounted just behind the throttle control.

Checked it out and bingo.happy days. Seems to be working well.

Click below for a vid

Total project cost €205